Published June 2023

Subscribe to receive latest resources on supply chain design

For decades, businesses relied on Excel spreadsheets to manage their supply chains. The simplicity of Excel and its wide availability made it the go-to tool for everything from inventory management to demand forecasting. However, as supply chains have grown increasingly complex, Excel has become an insufficient tool for managing these networks. In this blog, we’ll explore why you can no longer rely on Excel to design and manage your supply chain network.

Excel can be a great tool for managing small amounts of data, but as your supply chain grows, the amount of data you need to manage grows as well. Excel can quickly become cumbersome and difficult to work with when dealing with large datasets, leading to errors and inaccuracies that can impact your entire supply chain.

Excel was designed to be a general-purpose spreadsheet tool, not a supply chain management tool. This means that it lacks many of the features and functions that are critical for managing complex supply chains. For example, Excel does not offer advanced network optimization tools or real-time visibility into your entire supply chain. For example, number of variables in excel solver is limited to 200 whereas a typical supply chain involves thousands of variables.

Excel is a standalone tool that is not designed to integrate with other software applications. This means that data must be manually transferred between Excel and other systems, leading to errors and inefficiencies. In contrast, modern supply chain management solutions are designed to integrate with other systems and provide real-time data sharing and collaboration.

In today’s global economy, supply chain disruptions can have a significant impact on your business. Excel is not designed to provide real-time risk management and mitigation tools, leaving your business vulnerable to disruptions. Modern supply chain management solutions offer real-time risk management tools that can help you quickly identify and mitigate supply chain risks.

Finally, modern supply chain management solutions offer cost and time savings that Excel cannot match. By automating many of the tasks associated with managing a supply chain, these solutions can save your business time and money, allowing you to focus on other critical areas of your business.

Successfully transitioning from Excel to advanced supply chain planning could be the difference between your company not only surviving but thriving when the next big, global disruption hits. But the benefits go far beyond just the supply chain agility you can achieve when your end-to-end network is seamlessly connected. Based on LambdaSCS’s customer and industry benchmarks, an upfront investment in an advanced planning practice can save your organization millions, and not after a 10-year ROI period. On average, companies save 10-15% of their logistics cost when they ditch spreadsheets for AI-based optimization tools through reduced working capital, lower inventory carrying costs, and decreased manufacturing and logistics costs.

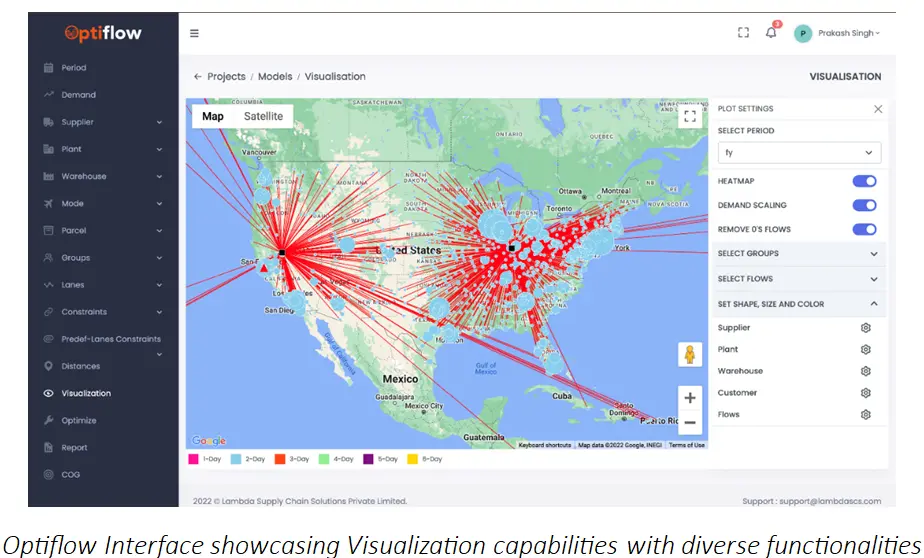

In conclusion, while Excel may have been sufficient for managing supply chains in the past, it is no longer an adequate tool for managing the complex, global supply chains of today. At Lambda Supply Chain Solutions, we offer a powerful supply network design product called Optiflow that offers several advantages over Excel. With Optiflow, you can gain access to advanced functionality, real-time visibility, seamless integration, advanced risk management tools, and cost savings. Contact us today to learn how Optiflow can help you optimize your supply chain network and stay ahead of the competition.