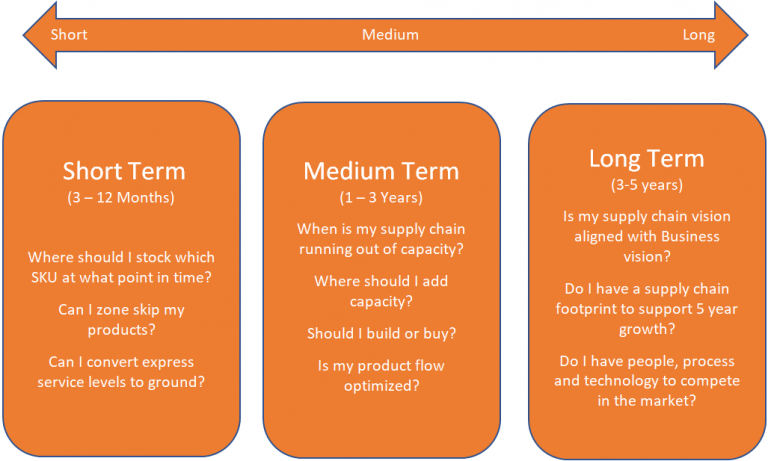

A digital supply chain twin consists of several products, supply chain nodes, transportation and inventory policies and constraints. Design criterion of a digital twin is informed by the type of decision that the Business wants to answer as explained in the previous section.

Top 9 Design criterions for a network model or a digital twin are:

1.PERIODS

A period defines the planning horizon used in the digital twin. A single period annual model would aggregate flows across weeks and months, whereas a quarterly period model would aggregate flows across each quarter.

Generally, depending on the type of problem (short, medium or long) periods should be decided. For e.g. For inventory planning, look at Business’s inventory planning cycle and then define periods for the model. Typically, a business that does inventory planning once every quarter, a 4 period model should be created.

For planning 5 year capacity decision, a 5 period model, where each period represents single year should be built.

OPTIFLOW ® has been used to create multi period models to inform both short and long term decisions.

2.PRODUCTS

A model can be built using most granular product in supply chain i.e. SKU or can it can be build at a relevant product category level.

For short term planning horizons, which are tactical in nature, a SKU Level model is advised so that inventory planning decisions can be answered accurately.

For medium to long term planning horizons, which are more strategic in nature, a product category level aggregation should be done as focus is more on capacity estimates and not optimal inventory positions at SKU level.

Typically, a 100-200 product model is advisable, if you are not using it for inventory planning. For inventory planning, network models can manage ~10,000 products but take far more time to solve. Using OPTIFLOW ®, we built a network model for a US based E-commerce client consisting of 6, 500 SKUs to inform inventory decisions.

3.CUSTOMERS

For US geography, that consists of 40K 5 digit zip codes, it is always advisable to aggregate them to 900-1000 3 digit zip codes. However, if the customer count is less (<2000), then a model can be created at actual customer locations to retain accuracy

4.FACILITY NODES

Supply chain nodes consist of suppliers, plants, warehouses and cross docking where the products are made or sourced from, stocked or flowed through to reach the end customer. These nodes need to have supply, product, storage and throughput capacity. Some of the nodes can also store inventory when inventory is modeled.

Nodes can also be used for creating a multi-tier distribution model where within ‘warehouses’, primary, secondary and tertiary warehouses and cross docking locations can be created.

A cross docking location is not a storage but a flow through location. A FedEx (or UPS and USPS) parcel hub is essentially a cross docking location can be used to simulate zone skipping.

Using OPTIFLOW ® we created a 3-Tier network model that had 3 plants, 7 warehouses and 60 cross docking locations (parcel hubs) to simulate an E-commerce distribution network with zone skipping.

Nodes also contain variable and fixed costs which need to be defined to capture total logistics cost

5.TRANSPORTATION MODES

This feature is used for defining what transportation modes exist between one node and another. Typical modes would be Full Truck Load, Less than Truck Load, Air, Ocean and Rail.

For E-commerce channels, parcel is the additional mode that needs to be defined. Parcel rating works on zones and product weight and needs a much complex rate table as input. These rates also change every year depending on parcel provider and should be refreshed.

OPTIFLOW ® has inbuilt parcel rating engine built using rates for leading parcel providers in North America and refreshed regularly. The software also gives option to the user to input customer parcel rates that have been negotiated between the client and parcel provider

6.LANES

Lanes are essentially ‘flow paths’ within which a product travels between nodes and from nodes to customers. These flow paths can be built at group level or individual node level. Once the lane is built, a transportation mode along with % split needs to be defined to cost out the volume flowing in the lane.

7.GROUPS

Groups are a very important feature of network design software. They enable user to setup transportation, inventory or cost policies that are common across elements of a group. These groups can be for products, customers, nodes, modes, and periods. For e.g. – we may have separate groups for Fast Moving Products and Slow-Moving Products, and tackle both differently in terms of their behavior.

8.INVENTORY TARGETS

Inventory targets are used as an input for the software to understand how many days of stock is required to be maintained at a certain DC location. These targets can vary depending on product type, DC location and even time of the year (like Peak vs Non-Peak months). These targets directly affect the inventory storage costs in a network and help us simulate real world inventory scenarios in our digital twin model.

9.CONSTRAINTS

Constraints can be of several types:

a) Flow constraints: These constraints are used to cap the flow between two nodes (or node and customers) at a group level by product / product group

b) Distance constraint: These constraints limit the distance products can travel between node groups.

c) Capacity constraints: These constraints restrict throughput from a facility at product / product group level

d) Pre-defined flow constraints: These constraints work at individual node and product level and primarily used to create baseline model for validation.

Creating a digital twin of your supply chain is both art and science. The design of the network model needs to be balanced between accuracy and speed, like a supply chain. Talking to a network design expert can help you save both time and cost when it comes to network optimization projects.

Have questions? Reach out to us on info@lambdascs.com