Plant inventory refers to the stock of raw materials and finished goods held within a manufacturing or production facility.

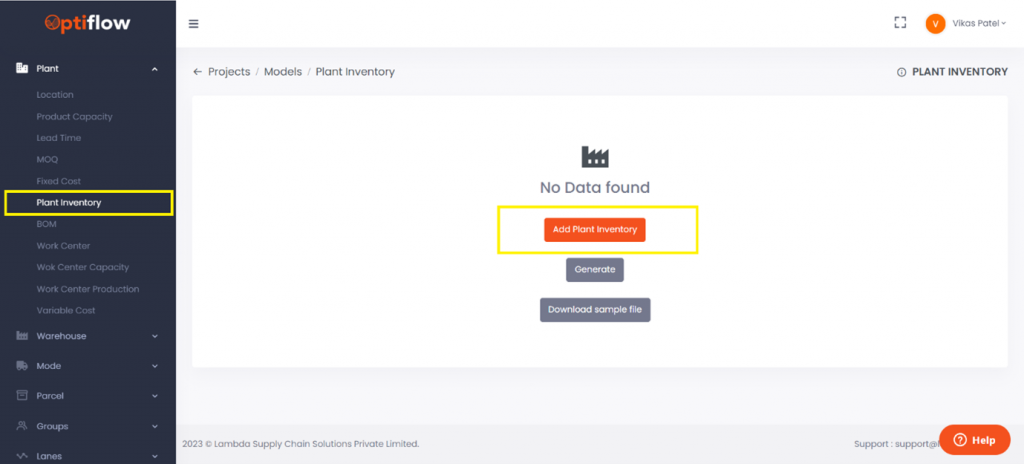

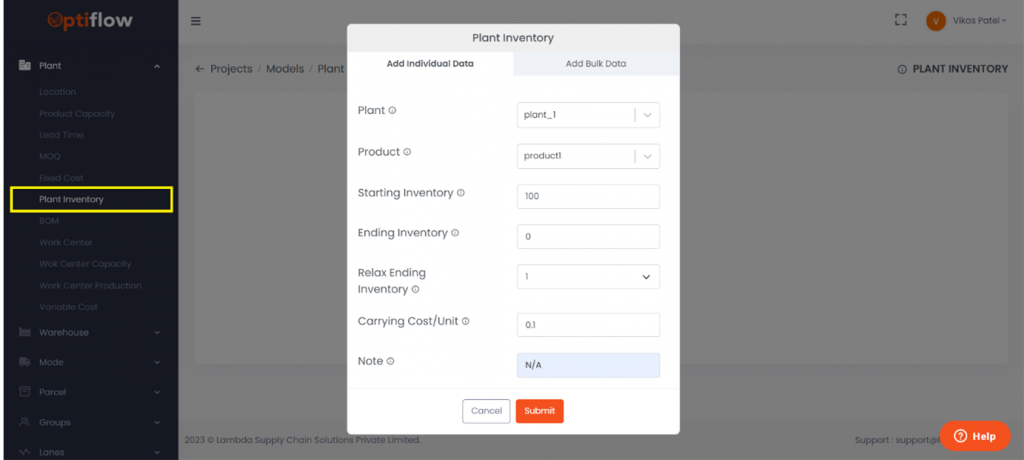

To add plant inventory, click on Plant Inventory under plants and then by clicking on add plant inventory, you can add individual data or bulk data under respective tabs.

| Table Description | |

| Plant | Plant from the plants location table to be selected/added in this column. |

| Product | Product from the product table to be selected/added in this column. |

| Starting Inventory | The initial inventory at the beginning of the first period is to be included in this column. |

| Ending Inventory | Desired Ending Inventory at the end of the last period to be added in this column. |

| Relax Ending Inventory | Inputting “0” will enforce the ending inventory to match the specified value in the ending inventory field. Conversely, inputting “1” will allow flexibility in achieving the ending inventory, aiming to bring it as close as possible to the specified value in the ending inventory field. |

| Carrying Cost/Unit | The relevant inventory carrying cost is to be included in the designated column for the chosen product at the specified plant. This carrying cost will be applied to each unit during every period and the total cost will be computed based on the average inventory during that period. |

| Note | Any remarks/comments can be added in this column. |